BIOCHAR BENEFITS FOR MORE SUSTAINABLE COFFEE Biochar, at its most basic, is carbonized organic material. It can be produced using a wide variety of low- to high-tech thermochemical conversion technologies, and from a wide variety of feedstocks. Although most often biochar is intended for direct use in soils as a soil amendment, there are other uses for biochar which can benefit the coffee industry across the entire supply chain. For example, biochar production can provide a highly sustainable method for managing residues as well as generating clean, renewable, distributed energy. This unique combination of benefits makes the use of biochar in coffee production valuable from both a climate change mitigation and climate change adaptation perspective.

After reading this latest IBI release, my recommendation is that as farmers, responsible vegetation managers, researchers and educators we should think that this information presented in the white paper is not just limited to Coffee production and / or to subtropical climate!

By linking the cascading effects and values we get a holistic picture and appreciate the multifaceted linkages and synergies.

It is a systems approach leading to a circular, regional economy with interested participants and potential visitors… – The Harvest Launceston Market every Saturday morning is the classic example where this can be experienced – zero waste is the goal and lots of ‘productive fun’ for all.

I am grateful for people like Kathleen Draper and her Associates who have voluntarily invested a great amount of time and energy over past years on this important work.

The benefits will be shared by many…

Frank

You can see read the Coffee & Biochar White Paper at

https://biochar-international.org/wp-content/uploads/2018/10/Coffee_FINAL_Feb-2015.pdf

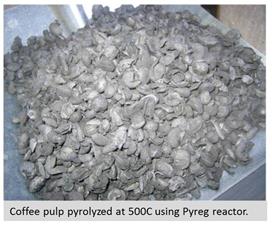

The moisture content of coffee husks is low, making conversion into biochar much easier than with pulp. Fairly simple technologies exist to press husks into briquettes for use as a cooking fuel and at least one project identified in this paper has created a customized cookstove to convert husks into biochar. Larger scale continuous feed machines would also be able to carbonize husks and could generate significant energy that could be used for drying beans or converted into electricity.”